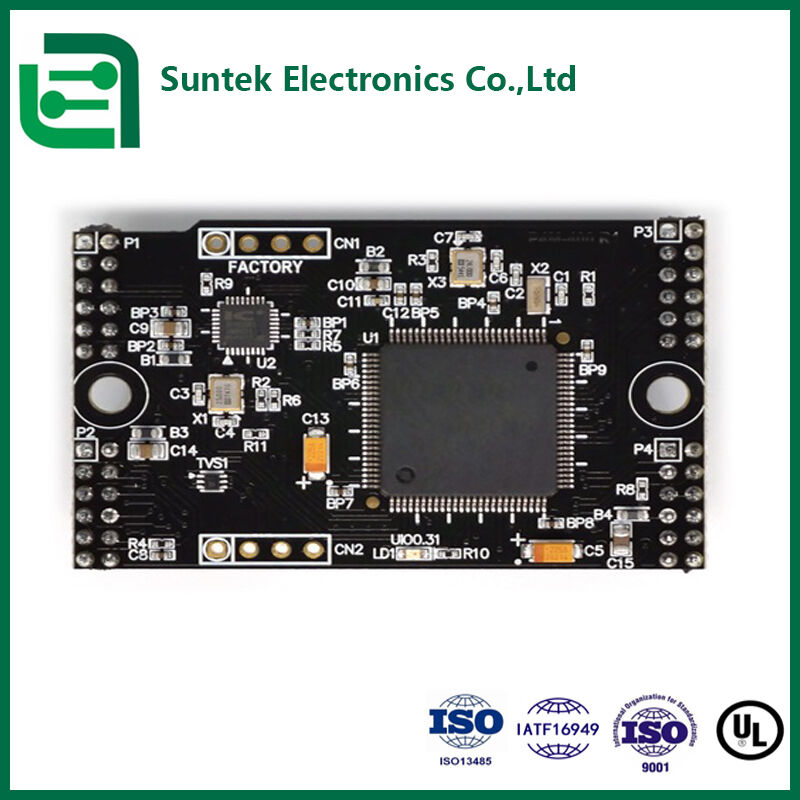

Industry Automation Control PCB Assembly Services

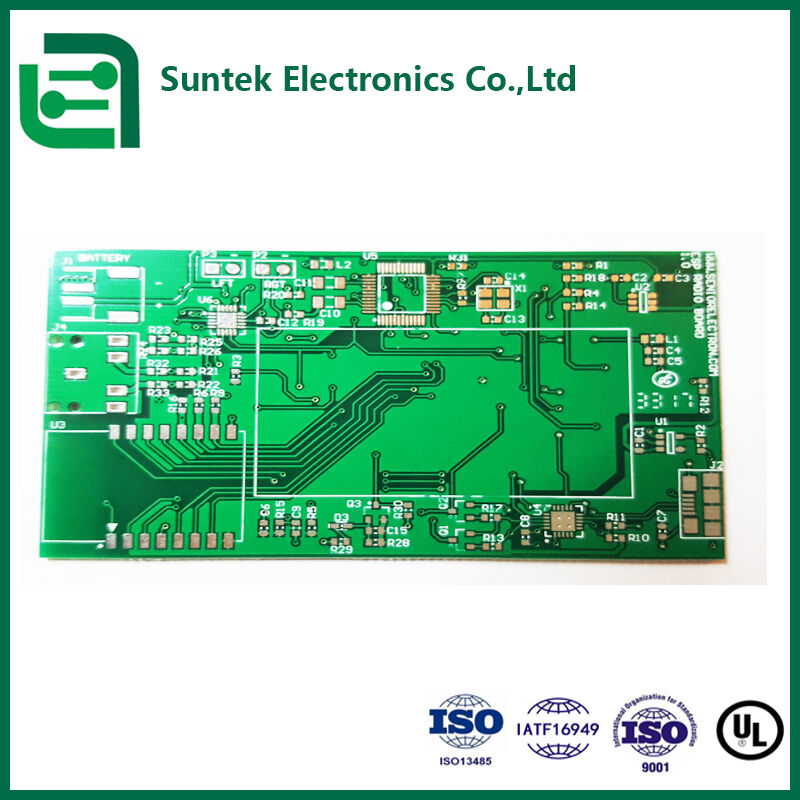

Professional PCB assembly services featuring green solder mask and comprehensive 100% electrical testing for quality assurance.

About Suntek Group

Suntek is a leading contract supplier in the EMS field, providing comprehensive one-stop solutions for PCB/FPC assembly, cable assembly, and box-build assembly.

Our Manufacturing Facilities

- Suntek Electronics Co., Ltd - Hunan Province, China

- BLSuntek Electronics Co., Ltd - Kandal Province, Cambodia

Certified with ISO9001:2015, ISO13485:2016, IATF 16949:2016 and UL E476377, we deliver qualified products with competitive pricing to clients worldwide.

Our Comprehensive Services

We transform your requirements into finished products:

- Gerber file and BOM conversion into real products

- Reverse-engineering services from physical samples

- Joint-design services to bring your ideas to life

Technical Specifications

| Specification | Details |

|---|

| Material Type | FR-1, FR-4, CEM-1, aluminum clad |

| Material Thickness (mm) | 0.4, 0.6, 0.8, 1.0, 1.2, 1.6, 2.0 |

| Layer Count | 1 to 8 Layers |

| Max. Board Size | 23.00" x 35.00" (580mm*900mm) |

| IPC Class | Class II, Class III, Class 1 |

| Annular Ring | 5 mil/side or Greater (Min. Design) |

| Finish Plating | HASL, Lead Free HASL, ENIG, OSP, immersion silver, immersion tin, immersion nickel, hard gold |

| Copper Weight | 0.5OZ-2OZ |

| Trace/Space Width | 3 Mils or greater |

| Drill Clearance | 0.1mm (laser drilling) |

| Plated Slots | 0.036 or greater |

| Smallest Hole (finished) | 0.1mm or greater |

| Gold Fingers | 1 to 4 Edge (30 to 50 Micron Gold) |

| SMD Pitch | 0.080" - 0.020" - 0.010" |

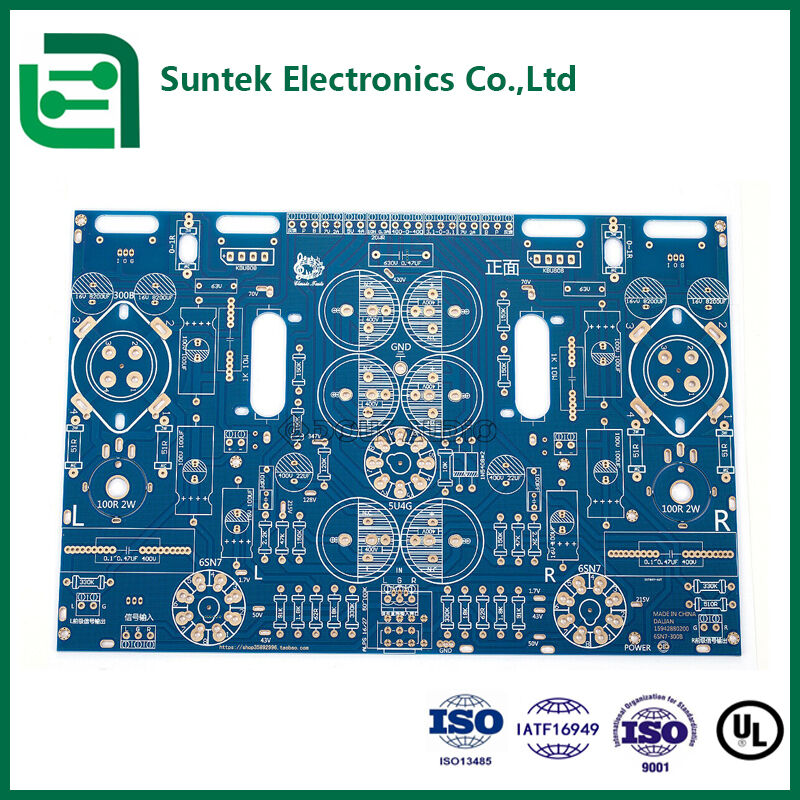

| Solder Mask Type | LPI Glossy, LPI-Matte, SR1000 |

| Solder Mask Color | Green, red, blue, black, white, yellow |

| Legend Color | White, yellow, black, red, blue |

| CNC Route Point | Any |

| Minimum Route Width | 0.031" |

| Scoring | Straight lines, jump scoring, panel edge to edge, CNC |

| Body Gold | HARD, IMMERSION (up to 50 MICRON GOLD) |

| Data File Format | Gerber 274x with embedder aperture |

| FAB. Drawing Format | DXF, HPGL, DWG, PDF, Gerber |

| E.T Testing | Flying probe, single sided, 1up plate, clamp shell, net list |

| Counter Sink/Counter Bore | Available up to 0.250 Diameter |

| Control Impedance | Yes |

| Blind Vias/Buried Vias | Yes |

| Peelable Mask | Yes |

| Carbon | Yes |

Complete Manufacturing Solutions

- PCB/FPC fabrication

- Components sourcing

- PCB/FPC assembly

- Custom cable/harness assembly

- Box build assembly

Assembly & Testing Services

- SMT, THT, BGA, 0201 Chips assembly

- AOI, X-Ray, ICT, FT, Burn-in testing

- Conformal coating or gluing

- High-mix, small to medium volume production

- ISO9001, ISO13485, TS16949 and UL certified

EMS Quality Advantages

- Strict product liability following IPC-A-610 standards

- Fluent English-speaking teams

- PDCA management tool implementation

- 100% electrical testing and visual inspection

- Comprehensive AOI inspection including X-ray, 3D microscope and ICT

- High-voltage testing and impedance control testing

- ISO9001, ISO13485, IATF16949 and UL certified

- No minimum order quantity requirements

- Specialized in low to medium volume production

- Quick and reliable on-time delivery

Why Choose Suntek?

As an experienced and reliable manufacturer, Suntek provides comprehensive one-stop services including PCB manufacturing and assembly for global customers with diverse project requirements.

Instant Quote Service

Receive our detailed quote within 24-48 hours with positive feedback on all project specifications.

Expert Technical Support

Our professional engineers provide comprehensive technical support from PCB design to turnkey assembly.

Advanced Automation

State-of-the-art automatic equipment ensures high efficiency, cost-effectiveness, and consistent quality.

Dedicated After-Sales Service

Continuous order tracking with instant updates throughout the production process from our customer service team.

Customer Support & Services

We maintain complete cost transparency with detailed BOM cost breakdown sharing and source components globally.

Proactive Communication

- Customer service procedures

- RMA procedures

- 8D reports for issue resolution

- PDCA (Plan-Do-Check-Action) methodology

Responsive Support

- 24-hour response to complaints and queries

- Weekly progress reports

- Dedicated customer support team

- Customer satisfaction surveys

Comprehensive After-Sales

- 1-year guarantee period for all products

- Free-of-charge repair services

- Rapid replacement of defective components

PCBA Assembly Process Flow

Frequently Asked Questions

Q1: What files do you use in PCB fabrication?

A1: Gerber files and PCB Auto CAD formats.

Q2: How do you ensure product quality?

A2: All products undergo 100% electrical testing. PCB assemblies include comprehensive AOI, ICT, functional testing, and 100% X-ray inspection for BGA components.

Q3: Can we visit your facilities?

A3: Absolutely. We welcome visits to our Suntek facility located in Xingsha Industrial Park, Changsha, Hunan province, China.

Q4: What are your typical lead times?

A4: Samples: 3-5 working days; Batch production: 7-10 working days (based on files and quantity); PCB assembly: 15-20 working days.

Q5: How do you protect customer information?

A5: We strictly maintain business confidentiality and protect customer designs. NDAs can be signed at any time.

Q6: How do we start working with you?

A6: Email your PCB layout file and BOM list. We provide confirmation within 12 hours and detailed quotes within 3-5 days.

Our advanced manufacturing equipment, professional engineering teams, comprehensive quality control, and efficient management ensure high-quality products and reliable on-time delivery. Our PCB assemblies are widely used in industrial control, automotive, telecommunications, medical equipment, consumer electronics, and more.

Manufacturing Facility Overview

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!